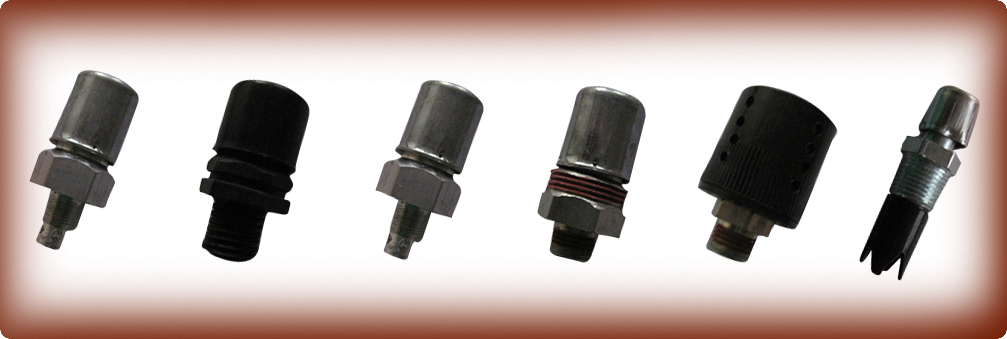

ANS : Same Breather is suitable for both application

ANS : No, same breather is suitable for all the vehicles.

Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum

ANS :Same can be fitted on all types of vehicles.

Yes, same breather ( just one part number) will be universally installed, adopted on all platforms, after the female thread size is standardized.

ANS :Yes, the concept is realized in totality.

ANS : Absolutely right. We design, manufacture, get customers feedback and again come back to the drawing board to re-design and follow the same path of designing, manufacturing …….. Enclosed circle as shown below.

ANS :It is suitable for life of the vehicle. However at schedule oil change time (servicing) instead of changing oil, viscosity of oil be tested and if its found in good condition, instead of changing oil the breather with fresh filter be installed to further prolong the oil life. This repeated till the oil is maintains in its prime health. Spend a penny and save a pound. Only experience will tell us, as to how much the lubricants life can be extended. .

ANS : Nothing much will happen with old breathers, just wash and serviced, lubricant’s life will continue to be extended to at lease twice its normal life, saving our customer’s a lot of money perennially.

ANS :No, normal servicing / washing will maintain it in good serviceable condition.

ANS :Since the pressure and suction valves opens at +1.5 p.s.i and -1.5 p.s.i. It so happens that in normal running condition of the vehicle usually pressure inside gear box / differential hovers between +1.5 p.s.i & -1.5 p.s.i. Only in extreme climate condition, it crosses above limits and open momentarily bringing down the pressure slightly (say from +1.5 to +1.4 or so) as the spring closes it, fast. Thus very small breathing takes place, occasionally. Besides the dust (SPM) settles around the fluff on the periphery (it doesn’t penetrate inside), which is cleaned during washing / servicing.

ANS :For extremely dusty condition, ASPRA Breather with external filter is available.

ANS :Yes, in fact ASPRA’S primary mission has been to protect mother Earth. (The inventor, being a Mining Engineer, in his fag end of life, has urge from within, to heal our mother Earth, which was exploited by him throughout his life as a mining Engineer).

ANS :Yes, we have continued R&D to improve the breather, so that quality product at most affordable price be provided to our auto manufacturers & customers.

ANS :Yes, very much negotiable, depending on the volume and future research, it is negotiable. Purpose of mentioning price in above context is to show that research has resulted in reduction of cost of manufacturing from three dollars to two dollars. With increased volume, automation and productivity improvement cost can be contained further

ANS :Yes, it has been fitted on lakhs of vehicles in India (Mahindra & Mahindra auto, HMT Tractors etc.) and abroad for last 5 years and continue to be fitted on more and more new platforms, around the globe

ANS :Only since last year (2013) marketing in India has been started. Almost all 70 possible customer in India has shown great interest and has started testing our BREATHER . Maruti Suzuki and Mahindra REVA have already approved our Breathers. M&M has approved our Breather for many more platforms and continue to test on more and more models. They are moving ahead to achieve goal of one part number one vendor philosophy, by installing our breather on all their platforms.

ANS :Story is told in Breather technology – a brief History.. Its like this. In 2008, we mastered ASPRA BREATHER designs and gave some samples in USA for testing. Borg Warner had our samples. M&M had manufactured some Gear box / Differential on design given by Borg Warner, but were facing problem of oil expulsion on testing. When they referred back to Borg Warner , they advised M&M to contact us for solution and we solved their problem with our breather instantly. So they started fitting our Breather on their new platforms.(Of course, they subjected our Breather to intense lab and field tests for almost a year, before adopting them).

ANS :We, earlier thought that we had developed the Breather for USA (robotic application). ASPRA WORLD was given responsibility to market it in USA. They couldn’t progress much as , since USA was reeling in acute recession from 2008 to 2012. Now USA is also catching up fast on our breather. Moreover, ASPRA Engineering India was focused on R&D, all these years. Now that the breather is 5/6 years old and successfully used on lakhs of vehicles in India as well as abroad, we have decided to market it in India and Abroad vigorously. So, in 2014 we intended to let the world know of our inventions and its benefit. ( It serves manufacturers, customers & mother Earth in equal proportions).

©2010 ASPRA Engineering India Pvt Ltd Privacy Policy Developed by @Bagwar Softwares